Selecting the Right Fastener for Your ACQ Pressure Treated Lumber Project

It is starting to warm up outside and you’ve finally decided to get to work on some yard projects, maybe replacing that gate that was damaged last year, or building some raised beds in your garden. But when you’re loading up your lumber you notice the tag “Pressure Treated” or “ACQ”. What exactly does that mean?

Pressure-treated lumber undergoes a chemical process that may cause the accelerated corrosion of metals that come in contact with the wood (like screws and other fasteners). Once the fasteners have corroded, replacing them can be an immensely time-consuming repair for you, depending on the project.

What Is Pressure-Treated ACQ Lumber?

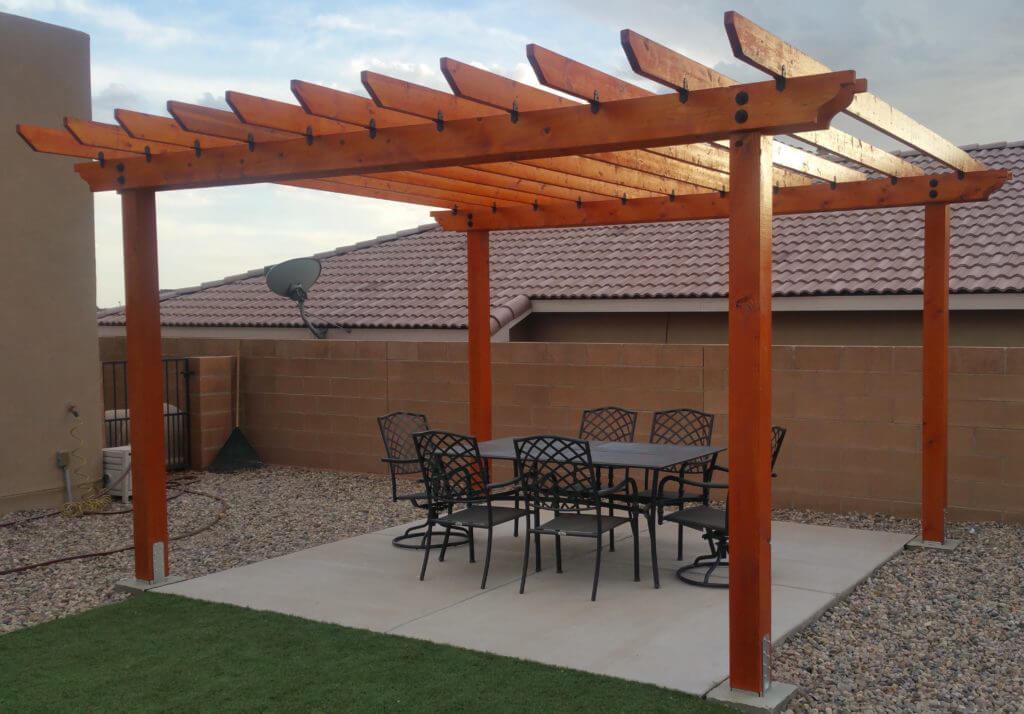

Pressure-treated lumber, also known as Alkaline Copper Quaternary (ACQ) lumber, is wood that is chemically treated to make it more resistant to rotting, and to repel insects. The wood is placed into pressurized tanks where chemicals are forced deep into the fibers of the lumber. This makes the wood exterior grade quality, and ideal for use in outdoor projects like fences, picnic tables, and decks.

What Happens If You Use the Wrong Fastener?

Pressure-treated wood has some amazing qualities, but unfortunately, the ability to play nice with metals is not one of them. Due to the high amount of copper chemicals in the wood, metals that come into contact with pressure-treated wood will become corroded unusually quickly.

This is due to a special type of corrosion called galvanic corrosion. It occurs when two different kinds of metal come into contact and are exposed to moisture. The copper in pressure-treated wood acts as one type of metal, and the hardware you use to build your project is the other. The accelerated corrosion that follows could be common rust, which often occurs with steel fasteners, or it could be pitting, which more often occurs with aluminum and certain kinds of stainless steel.

The speed of corrosion is affected by several factors, including the location of the project. For example, hardware used on a deck in an arid environment will likely last longer than hardware used on a deck in humid locations like Georgia, Alabama, and Florida, since humidity speeds up the rate of corrosion.

What Type of Fastener to Look For

Since galvanic corrosion occurs when two different metals come into contact, to prevent it we need to make sure that the metal that makes up the fasteners we’re using doesn’t come directly into contact with the chemically-treated wood.

One way to avoid this is to use hot-dipped galvanized (HDG) fasteners. These fasteners, typically steel, are dipped into a vat of molten zinc at a temperature of about 850 degrees Fahrenheit. The result is a zinc coating bonded to the metal that delays corrosion. However, not all HDG fasteners are equal. When you choose HDG hardware, make sure they are ASTM A153 standard. This ensures the coating reaches a level of quality and thickness. If a lower-quality alloy is used in dipping the hardware, the coating may not last. In the same way, if the coating is too thin, not uniform, or has too many blemishes, then the hardware may still corrode.

Another option is a product with a finish such as powder coating. This acts in the same general fashion as HDG, by separating the metal from the wood. But while in HDG products the zinc is bonded to the metal by extreme heat, powder coating is applied more conventionally. In this process, the powder coating is sprayed on and electrostatically bonds to the metal. The product then usually cures in an oven. This creates a very durable bond that is much more permanent than conventional paint. Products that are both hot-dipped galvanized and powder coated are some of the most durable products on the market when it comes to standing up to the effects of ACQ treatment in lumber.

Some manufacturers also sell hardware designed for ACQ lumber that’s been polymer coated, rather than powder coated. This method is similar to powder coating since it puts a tough, corrosion-resistant coating on the metal that protects it from the chemicals in the wood. Polymer-coated hardware tends to be more slippery than powder coated, though, meaning it can be a useful treatment for hardware like screws as it reduces friction on the threads.

What About Stainless Steel and Other Metal Fasteners?

Because of the high chromium content in stainless steel which prevents corrosion, it’s also a good choice for any fasteners that you plan to use on pressure-treated wood. There are a couple things to keep in mind though:

- Stainless steel is much more expensive than steel, whether it be bare, powder coated, or HDG. Consider a double shear face mount joist hanger. A galvanized version of this hardware will cost around a $1, while the same hanger made of stainless steel will likely cost around $10.

- You’ll need to select the right grade of stainless steel. 304, 305, and 316 are ideal for corrosion resistance. 410 grade is made with hardness in mind and includes less chromium, the key alloy that inhibits corrosion. This makes it less desirable when working with treated lumber.

- You cannot use stainless steel in conjunction with HDG, brass, or copper components, since putting these metals in contact will cause galvanic corrosion. In other words, if you decide to use stainless steel for your project, you’re all in—you won’t be able to mix metals.

Choosing the Right Fastener for Pressure-Treated Wood

While stainless steel is a perfectly viable option when it comes to hardware for pressure-treated wood, many people choose a product with a powder coating or polymer coating finish. Whether powder-coated aluminum, powder-coated HDG steel, or polymer-coated steel, these products combine corrosion resistance with more choices in color and finish style. Ornamental Wood Ties (OWT) products like truss base fans, post to beam supports, and gate accessories are decorative and designed to be seen, meaning they can add additional flair to your project, and there’s no need to make sure they’re hidden when the project is finished.

If you’re looking for easy-to-use, attractive fasteners for your pressure-treated lumber project, take a look at OZCO’s wide selection of decorative, innovative outdoor ties and fasteners. OZCO products meet or exceed building codes and have a protective and decorative coating to take your project to the next level. Each piece of our hardware is designed to work with every other piece, so you don’t have to worry about corrosion issues due to mixed materials. They also have a selection of materials for your fencing, decking, and railing projects at Fortress Building Products.

Leave a Reply